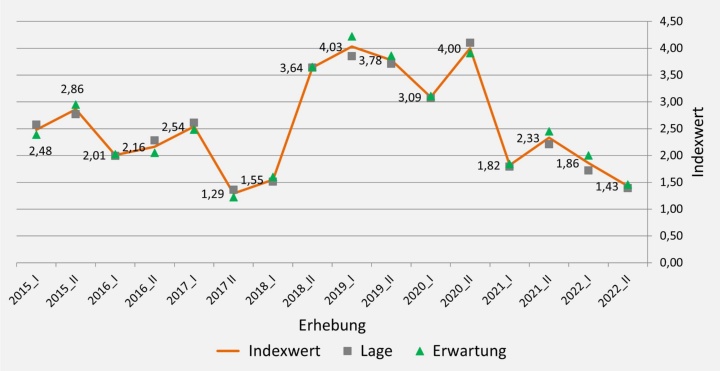

According to the current survey by the Institute for Energy Efficiency in Production (EEP) at the University of Stuttgart, the Energy Efficiency Index (EEI) continues to rise while the Investment Index continues to decline. The Importance Index and Productivity Index also continue to rise. In plain language, this means that energy efficiency is important to companies. However, money for further investment is being withheld in uncertain times. The results of the index have been presented to the public in an online TEAMS event on March 14, 2023

Since 2013, the Institute for Energy Efficiency in Production (EEP) at the University of Stuttgart has been surveying current and planned activities by German industrial companies in terms of energy efficiency on a semi-annual basis. The Energy Efficiency Index (EEI) is created in collaboration with the German Energy Agency (dena), the Federation of German Industries (BDI), the Fraunhofer IPA, TÜV Rheinland, and other partners. Over 900 participants commented on the three sub-indices during the current survey period. The special issues in Winter concerned high gas prices and uncertain gas supplies.

Gas prices incentivize energy efficiency

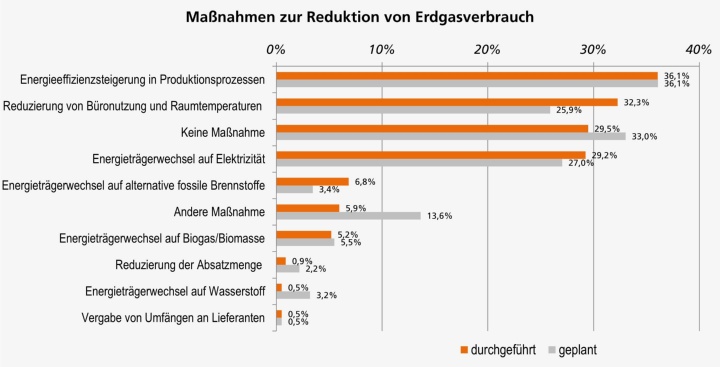

Many German companies are looking for ways out of the gas crisis. The “favorite solution” here is increased energy efficiency. Of course, this is also good for the climate. But because prices are still high, there is also bad news. Most companies chose – or rather are forced – to pass on the additional energy costs from the manufacture of products to their customers.

Although the new energy-saving ordinance regulates lighting and temperature in public spaces, one-third of companies continue to remain inactive and have not planned any measures. Approximately 40% of these companies pass on more than 75% of their additional energy costs or other additional costs to their customers.

Gas prices are one reason for companies to act. The EEP survey asked them about their alternatives. For alternative energy sources, electricity is preferred over fossil fuels or biomass. Only 22% of companies use a heat pump to generate process heat. Half of the companies are planning – or have already introduced – digitized recording of their energy consumption data and are monitoring their electrical consumption. This is a basic prerequisite for being able to save further energy.

Low investment index – fear of turbulence

The willingness of industry to invest decreased considerably during the survey period. This trend has been observed since the beginning of 2021. “The reason seems to be the pandemic and the energy crisis,” said Professor Alexander Sauer, Director of the EEP. “High energy prices and the related uncertainty are obviously triggering concerns about new investments and are reflected in a lower investment index.”

“We’re feeding off the investment-intensive years in energy efficiency improvements. Once the low-investment measures that are being addressed again have been implemented, it will probably take higher investments in energy efficiency in order to be able to achieve considerable progress,” says Sauer.

Expert Contact:

Institute for Energy Efficiency in Production (EEP), Project Management of Energy Efficiency Index

Laura Jung Tel: +49 (711) 970-1215, Kerim Torolsan Tel: +49 (711) 970-1493

Some results of the Energy Efficiency Index and pictures